We spent an even larger sum of money yesterday. Noooo... well, yes. Lawyers aren't the only people who require engagement letters with retainer deposits. We officially teamed up with Destree Design Architects yesterday. Despite working on highly-stylized places like Samba and Fromagination, the folks at Destree are very grounded and approachable. Helping us evaluate locations and design our facility won't be as lucrative as some of their other projects, but they're cool with that.

I spent the last day of 2008 doing something I love: bottling a batch of Belgian Pumpkin Ale. Bottling is ok on a homebrew scale. There, I'm not a hypocrite.

Wednesday, December 31, 2008

Tuesday, December 23, 2008

Big Money

We wrote our first four-figure check today... scary! We've now officially retained a securities lawyer to review our investment offering. Up next: take a few days off to enjoy our families' culinary skills because we can no longer afford food. After that, we'll retain an architect and commence an intensive location search. We practiced this afternoon by checking out an unexpectedly awesome property. As if our spirits weren't high enough, the House Ale tastes fantastic - my experiments with organic ingredients and unfamiliar yeast strains are beginning to pay off in spades. Have a great holiday!

Wednesday, December 10, 2008

Holiday Beer

Tuesday, December 9, 2008

Radio Radio

Dean Coffey, the brewmaster at Ale Asylum, thinks that anyone who wants to open a brewery in Wisconsin needs their head examined. I think that anyone who wants to run a bottling line needs their head examined. Joking aside, Dean really captured the essence of Wisconsin's Brewpub Bill in this Beer Talk Today interview:

MBR Podcast 12/9/08

Can we still call the bill SB224? I believe the original proposal was sent back to committee due to overwhelming industry opposition. Calling it "the 2007-2009 budget" isn't very descriptive, though.

MBR Podcast 12/9/08

Can we still call the bill SB224? I believe the original proposal was sent back to committee due to overwhelming industry opposition. Calling it "the 2007-2009 budget" isn't very descriptive, though.

Friday, December 5, 2008

More Models

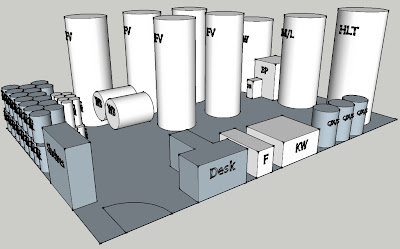

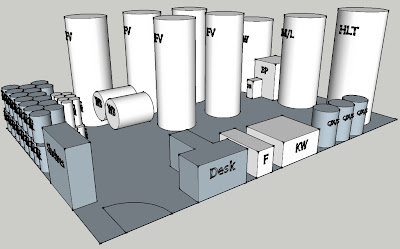

The picture below is of a cold room. My initial sizing estimate, which assumed that 15% of the cold room floor would be empty, didn't have nearly enough space to arrange the tanks and kegs in a usable fashion. The modeling process convinced me to bump the empty floor space to 50%.

The next picture shows a mill room. It's not much to look at, but it was nice to verify that my initial sizing estimate would fit a mill, two pallets of malt and a pallet-wide door path.

I went two for three on my initial sizing estimates. Not bad for my first time!

The next picture shows a mill room. It's not much to look at, but it was nice to verify that my initial sizing estimate would fit a mill, two pallets of malt and a pallet-wide door path.

I went two for three on my initial sizing estimates. Not bad for my first time!

This Year's Model

A 3D model of the brewery, that is!

I was just hoping to make a crude 2D CAD drawing, but I couldn't find any free software for my old Macintosh. Eventually, I stumbled across Google Sketchup. It's totally counter-intuitive if you've used other 3D modeling programs, but I'm getting the hang of it. All I need it for is to quickly estimate whether or not a given space is big enough to house a brewery. I had no trouble fitting the equipment onto an ambiguous rectangle with the same square footage as my sizing estimates, so I've done a good job so far.

I was just hoping to make a crude 2D CAD drawing, but I couldn't find any free software for my old Macintosh. Eventually, I stumbled across Google Sketchup. It's totally counter-intuitive if you've used other 3D modeling programs, but I'm getting the hang of it. All I need it for is to quickly estimate whether or not a given space is big enough to house a brewery. I had no trouble fitting the equipment onto an ambiguous rectangle with the same square footage as my sizing estimates, so I've done a good job so far.

Saturday, November 29, 2008

Short Week

I hope all y'all had a great Thanksgiving! It was a short week for me, both because of the holiday and because I'm running low on things to do. A lot of the near-term tasks are out of my hands: our lawyer is making a few changes to our operating agreement, Jane is updating her bio for the business plan and our real estate agent is searching for buildings. Once the operating agreement is ready, another attorney will review our investment offering for compliance with securities and tax laws. In the meantime, I scheduled meetings with an accountant and an architect - as well as a couple of property showings - for next week.

Jane and I know what architects do in the general sense, but we're pretty clueless about the specifics. We know that Madison won't give us a building permit without facility drawings that are signed by a registered architect or engineer, so we'll probably need to work with one at some point. Some of the things we don't know are when we should start talking with architects, whether or not they can help us evaluate sites, and how we can approach them without sounding like idiots. This website was a huge help:

American Institute of Architects: How Design Works

In other news, my wife is pregnant! Her due date is early June. I could write pages about how excited I am, but that's not why you're here. As far as it relates to the business, it basically means that I'll have to be making money by July. Daycare alone will cost more than my wife's salary will be able to cover. The brewery won't need to be open by July, which isn't remotely possible anyway, but I'll either need to have raised enough money by then to start paying myself or I'll need to get a part-time job. The responsible future parent in me is screaming "get a job now!" while a more optimistic part of my psyche is saying "you're too far along - you'll have to quit any job you take in two months." If I knew what I know now, I'd have looked for a job as soon as I got back from Vermont. I'd be much farther away from opening the pub, but I'd be in better financial shape and I wouldn't feel nearly as weighed down by urgency. How naive was I to think that I'd be renovating a facility several months ago? Am I still being naive in hoping that I can raise $600K and find a location before next summer? Jane could have spent the last year working abroad instead of lingering at a job that she hates. I could have gotten another year of commercial brewing under my belt, or I could have learned to bartend, cook or wait tables. I hope I won't be saying the same things at this time next year.

Jane and I know what architects do in the general sense, but we're pretty clueless about the specifics. We know that Madison won't give us a building permit without facility drawings that are signed by a registered architect or engineer, so we'll probably need to work with one at some point. Some of the things we don't know are when we should start talking with architects, whether or not they can help us evaluate sites, and how we can approach them without sounding like idiots. This website was a huge help:

American Institute of Architects: How Design Works

In other news, my wife is pregnant! Her due date is early June. I could write pages about how excited I am, but that's not why you're here. As far as it relates to the business, it basically means that I'll have to be making money by July. Daycare alone will cost more than my wife's salary will be able to cover. The brewery won't need to be open by July, which isn't remotely possible anyway, but I'll either need to have raised enough money by then to start paying myself or I'll need to get a part-time job. The responsible future parent in me is screaming "get a job now!" while a more optimistic part of my psyche is saying "you're too far along - you'll have to quit any job you take in two months." If I knew what I know now, I'd have looked for a job as soon as I got back from Vermont. I'd be much farther away from opening the pub, but I'd be in better financial shape and I wouldn't feel nearly as weighed down by urgency. How naive was I to think that I'd be renovating a facility several months ago? Am I still being naive in hoping that I can raise $600K and find a location before next summer? Jane could have spent the last year working abroad instead of lingering at a job that she hates. I could have gotten another year of commercial brewing under my belt, or I could have learned to bartend, cook or wait tables. I hope I won't be saying the same things at this time next year.

Saturday, November 15, 2008

Unofficial Accountability Update

Last week was a pretty busy one at RePublic HQ. I met with a couple of commercial Realtors to get the location search rolling, which I believe will be important to our success because bars and restaurants are usually sold without being advertised. Since a restaurant for sale would probably lose huge amounts of business after appearing in a classified ad, it makes sense for its owner to try and conduct the sale by networking through a real estate agent. Whether Jane and I buy an existing business or take over the lease of an already-vacated facility, I think the cost of startup will necessitate that we move into a location with tavern infrastructure in place.

Between meeting with realtors, I met up with a commercial kitchen designer to make sure we're looking for locations in the right size range. The designer I met with was surprised that I contacted him directly because he's usually recruited by architects. His typical role - and I'm simplifying here - is to determine which kitchen equipment will be required to execute a particular foodservice concept, work with a design team (typically coordinated by the project architect) to determine the kitchen layout, and inspect the equipment deliveries to ensure that the terms of purchase were satisfied. The meeting was very helpful, but the location we choose will play a large part in determining whether or not we hire a designer. If we're able to inherit a fully-equipped pub, we probably won't need one. If our eventual location requires an overhaul, hiring a designer would probably be money well-spent. The good news for now is that my sizing estimates were solid.

The hop search took a turn toward urgency as I continued to talk with HopUnion. The dealer told me that most of the varieties I'm looking for are 80% contracted for next year, meaning that 80% of the expected 2009 crop has already been purchased. I plan on committing to a contract next week, after doing a bit of last-minute scrambling to see what else is out there. These will probably be my options:

1. Talk with another US hop dealer to see which organic varieties they expect to have available for contracting. I received a return call from a sales rep last week, but he wasn't around when I called back. If the dealer has what I'm looking for, I'll sign a contract with them.

2. Sign a one-year contract with HopUnion for non-organic hops. The grower I'm buying my 2009 Cascades from expects to plant more varieties next summer. It usually takes a minimum of two years for newly-planted hops to produce worthwhile yields, which means I could be buying all Wisconsin hops by the fall of 2010.

3. Sign a three-year contract with New Zealand Hops for organic varieties that will impart a harsh bitterness to my beer.

I'm optimistically hoping that option #1 bears fruit, but my fallback plan is option #2. Buying organically is one of my long-term goals, but I can't justify the combination of shipping from New Zealand (i.e. trading one environmental benefit for another), committing to buying non-local hops for three years and compromising on my desired specifications. Option #3 was a lot more attractive five months ago when it was my only option.

Jane and I also received some excellent business plan advice from an experienced investor. His general advice was to elaborate more on ourselves (we should be trying to convince people to believe in us as much as our idea), remove tavern management specifics (e.g. menu items and employee policies) so we'll have the flexibility to adapt the business to its customers, and include more local market data (which is admittedly difficult to find). The meeting actually made me excited to revise the business plan, which I plan to do in conjunction with finalizing a hop supply next week. In the back of my mind, I'll be getting ready to ask some architects how they're typically involved in evaluating potential tavern locations.

Between meeting with realtors, I met up with a commercial kitchen designer to make sure we're looking for locations in the right size range. The designer I met with was surprised that I contacted him directly because he's usually recruited by architects. His typical role - and I'm simplifying here - is to determine which kitchen equipment will be required to execute a particular foodservice concept, work with a design team (typically coordinated by the project architect) to determine the kitchen layout, and inspect the equipment deliveries to ensure that the terms of purchase were satisfied. The meeting was very helpful, but the location we choose will play a large part in determining whether or not we hire a designer. If we're able to inherit a fully-equipped pub, we probably won't need one. If our eventual location requires an overhaul, hiring a designer would probably be money well-spent. The good news for now is that my sizing estimates were solid.

The hop search took a turn toward urgency as I continued to talk with HopUnion. The dealer told me that most of the varieties I'm looking for are 80% contracted for next year, meaning that 80% of the expected 2009 crop has already been purchased. I plan on committing to a contract next week, after doing a bit of last-minute scrambling to see what else is out there. These will probably be my options:

1. Talk with another US hop dealer to see which organic varieties they expect to have available for contracting. I received a return call from a sales rep last week, but he wasn't around when I called back. If the dealer has what I'm looking for, I'll sign a contract with them.

2. Sign a one-year contract with HopUnion for non-organic hops. The grower I'm buying my 2009 Cascades from expects to plant more varieties next summer. It usually takes a minimum of two years for newly-planted hops to produce worthwhile yields, which means I could be buying all Wisconsin hops by the fall of 2010.

3. Sign a three-year contract with New Zealand Hops for organic varieties that will impart a harsh bitterness to my beer.

I'm optimistically hoping that option #1 bears fruit, but my fallback plan is option #2. Buying organically is one of my long-term goals, but I can't justify the combination of shipping from New Zealand (i.e. trading one environmental benefit for another), committing to buying non-local hops for three years and compromising on my desired specifications. Option #3 was a lot more attractive five months ago when it was my only option.

Jane and I also received some excellent business plan advice from an experienced investor. His general advice was to elaborate more on ourselves (we should be trying to convince people to believe in us as much as our idea), remove tavern management specifics (e.g. menu items and employee policies) so we'll have the flexibility to adapt the business to its customers, and include more local market data (which is admittedly difficult to find). The meeting actually made me excited to revise the business plan, which I plan to do in conjunction with finalizing a hop supply next week. In the back of my mind, I'll be getting ready to ask some architects how they're typically involved in evaluating potential tavern locations.

Friday, November 14, 2008

How Stupid Is It?

Complaining about the Brewpub Bill is the closest I'll likely get to writing a regular feature on this weblog. Thanks to the bill's existence, RePublic will be required by law to sell other breweries' beer. If Dotty's was suddenly forced to sell another restaurant's burgers, you might ask "how did that other restaurant get so much political influence, and how could our legislators cater to it so shamelessly?"

Since the law doesn't quantify an amount to sell, I assume that I'd need to have an alternative beer available at all times. After exhaustive research and number crunching, I'm projecting that RePublic will sell one six-pack of it per year (rounded up to the nearest six-pack). Yes, that will allow me to have a bottle on-hand for anyone who wants to order one. If I can't find a distributor who's willing to drive to my pub every four years to sell me a case of beer, will the courts force me to stock excess inventory and/or spend money to advertise a beer that I didn't brew?

Changing gears, sort of, an ideal situation would be to have a brewery in the same building as the pub. However, in these tough economic times, it would be far less capital-intensive (i.e. easier to raise the required money) to open a pub in an existing tavern and build an off-site brewery in some inexpensive warehouse space. Until October of last year, we would have had that option. Boo to the Brewpub Bill.

Since the law doesn't quantify an amount to sell, I assume that I'd need to have an alternative beer available at all times. After exhaustive research and number crunching, I'm projecting that RePublic will sell one six-pack of it per year (rounded up to the nearest six-pack). Yes, that will allow me to have a bottle on-hand for anyone who wants to order one. If I can't find a distributor who's willing to drive to my pub every four years to sell me a case of beer, will the courts force me to stock excess inventory and/or spend money to advertise a beer that I didn't brew?

Changing gears, sort of, an ideal situation would be to have a brewery in the same building as the pub. However, in these tough economic times, it would be far less capital-intensive (i.e. easier to raise the required money) to open a pub in an existing tavern and build an off-site brewery in some inexpensive warehouse space. Until October of last year, we would have had that option. Boo to the Brewpub Bill.

Saturday, November 8, 2008

The Hop Report

In the northern hemisphere, hops are typically harvested in September. Earlier in the year, I tried to contract some hops for this year's harvest (i.e. buy them in advance so that my supply would be guaranteed). I was unsuccessful, which ended up being a good thing for two reasons:

1. Opening the pub is going slower than I expected, so I probably won't need hops until after the 2009 harvest.

2. The 2008 crop was better than it was projected to be, so availability is up and prices are down. If I had signed a contract, I would have paid higher prices than the current market value.

I recently talked with Hopunion - the major hop supplier of the craft brewing industry - about contracting some hops for the 2009 harvest. It's looking like I won't have any problems. I could sign a contract right now, but I'm going to hold off for a few months. Doing so will give me a better idea of when I'll need hops, will allow the hop prices stabilize some more, and will give me time to look for organic hops (which Hopunion sells very little of).

Organic hops are tricky. First off, they're difficult to grow. Hops are prone to a variety pests and diseases that thrive in the US and Europe. As such, most of the world's organic hops are grown in New Zealand. Secondly, the number of existing varieties are extremely limited. I've been experimenting with a bittering hop from New Zealand called Pacific Gem, but I haven't been very happy with the results. It lends a harsh bitterness to beer (due to high co-humulone levels, if you must know), which wouldn't be an issue if I used a variety such as Nugget, Magnum, Simcoe or Horizon - none of which are available organically. Traditional styles of beer that depend on specific hop characteristics simply can't be brewed with organic hops because, again, the varieties don't exist. Thirdly, organic hops are expensive. Growing hops without pesticides results in low yields, government certifications cost money, and shipping across the ocean is not cheap.

As a result, most certified organic beers probably don't have a lot of organic hops in them. To receive the standard organic certification from the USDA, 95% of the total ingredients (by weight) need to be certified organic. A typical 7-barrel beer recipe looks something like this:

Malted barley - 500 lbs

Hops - 5 lbs

In the above recipe, hops are less than 1% of the total weight. Even a hoppy pale ale, using the same amount of grain, would probably only have about 10-15 lbs of hops in it. Because hops are such a small amount of the total ingredient weight, certified organic beer can be produced with no organic hops whatsoever. A USDA rule change has been proposed that would require each type of ingredient to be 95% organic by weight, but I don't believe it's been implemented yet.

I do have a source for one organically-grown hop variety - Cascades from Gorst Valley Hops in Mazomanie - but the hops won't be certified. Due to the expense and hassle of certification, a lot of farmers simply don't want to deal with it. James, the Gorst Valley farmer, takes it a step further and claims that an organic certification doesn't ensure that something is organic. He told me an interesting story about visiting a certified organic farm that sprayed chemical pesticides on their crops. They were able to get away with it because the pesticides were in containers that previously held substances that were approved for organic production, and the inspectors didn't look any farther than the labels on the containers. James looks at not certifying his hops as an opportunity to educate people on what sustainable farming is really about.

Still, it seems like a formal certification does a lot for consumer confidence. What do you think? Would you rather buy beer made with non-certified organic hops grown down the road, or would you rather buy beer made with certified organic hops shipped from New Zealand?

1. Opening the pub is going slower than I expected, so I probably won't need hops until after the 2009 harvest.

2. The 2008 crop was better than it was projected to be, so availability is up and prices are down. If I had signed a contract, I would have paid higher prices than the current market value.

I recently talked with Hopunion - the major hop supplier of the craft brewing industry - about contracting some hops for the 2009 harvest. It's looking like I won't have any problems. I could sign a contract right now, but I'm going to hold off for a few months. Doing so will give me a better idea of when I'll need hops, will allow the hop prices stabilize some more, and will give me time to look for organic hops (which Hopunion sells very little of).

Organic hops are tricky. First off, they're difficult to grow. Hops are prone to a variety pests and diseases that thrive in the US and Europe. As such, most of the world's organic hops are grown in New Zealand. Secondly, the number of existing varieties are extremely limited. I've been experimenting with a bittering hop from New Zealand called Pacific Gem, but I haven't been very happy with the results. It lends a harsh bitterness to beer (due to high co-humulone levels, if you must know), which wouldn't be an issue if I used a variety such as Nugget, Magnum, Simcoe or Horizon - none of which are available organically. Traditional styles of beer that depend on specific hop characteristics simply can't be brewed with organic hops because, again, the varieties don't exist. Thirdly, organic hops are expensive. Growing hops without pesticides results in low yields, government certifications cost money, and shipping across the ocean is not cheap.

As a result, most certified organic beers probably don't have a lot of organic hops in them. To receive the standard organic certification from the USDA, 95% of the total ingredients (by weight) need to be certified organic. A typical 7-barrel beer recipe looks something like this:

Malted barley - 500 lbs

Hops - 5 lbs

In the above recipe, hops are less than 1% of the total weight. Even a hoppy pale ale, using the same amount of grain, would probably only have about 10-15 lbs of hops in it. Because hops are such a small amount of the total ingredient weight, certified organic beer can be produced with no organic hops whatsoever. A USDA rule change has been proposed that would require each type of ingredient to be 95% organic by weight, but I don't believe it's been implemented yet.

I do have a source for one organically-grown hop variety - Cascades from Gorst Valley Hops in Mazomanie - but the hops won't be certified. Due to the expense and hassle of certification, a lot of farmers simply don't want to deal with it. James, the Gorst Valley farmer, takes it a step further and claims that an organic certification doesn't ensure that something is organic. He told me an interesting story about visiting a certified organic farm that sprayed chemical pesticides on their crops. They were able to get away with it because the pesticides were in containers that previously held substances that were approved for organic production, and the inspectors didn't look any farther than the labels on the containers. James looks at not certifying his hops as an opportunity to educate people on what sustainable farming is really about.

Still, it seems like a formal certification does a lot for consumer confidence. What do you think? Would you rather buy beer made with non-certified organic hops grown down the road, or would you rather buy beer made with certified organic hops shipped from New Zealand?

Sunday, November 2, 2008

Fun With Labels

Sunday, October 26, 2008

Overlooked Business Advice

If you plan on opening a business that requires outside investment, you'll need to learn about securities laws. This website will get you started:

Small Business and the SEC

If you're in my boat, i.e. you want to privately raise a small amount of money (relative to Microsoft), you'll probably be exempt from having to register your investment offering. If that's the case, you should have around $10,000 on-hand for a lawyer to translate the government regulations into a human language, write your offering documents and prepare any required forms. If that's not the case, you should expect to pay around $40,000 for a non-abridged version of the same services. Just so you know.

Investing is for rich people. No conspiracy theories here - I believe it's a natural consequence of laws that are intended to protect investors - but that doesn't make it any less frustrating for me. Logistics aside, Jane and I would love to raise money from everyday people like ourselves. Unfortunately, exemptions from securities registration (which we can't afford to not qualify for) exist primarily for these types of scenarios:

-Unlimited number of accredited investors. For the most part, accredited investors are people with net worths over $1M and/or who earn over $200K a year.

-X or fewer non-accredited investors. X = 25 for Wisconsin, which (and this is total BS) includes out-of-state investors. This means that if you need to raise $750K, each investor would need to contribute an average of $30K.

-Private offerings only. If this post implied that I was offering you a share of RePublic equity, I'd already be disqualified from this type of exemption.

Now you know something that most introductory business guides don't tell you.

Small Business and the SEC

If you're in my boat, i.e. you want to privately raise a small amount of money (relative to Microsoft), you'll probably be exempt from having to register your investment offering. If that's the case, you should have around $10,000 on-hand for a lawyer to translate the government regulations into a human language, write your offering documents and prepare any required forms. If that's not the case, you should expect to pay around $40,000 for a non-abridged version of the same services. Just so you know.

Investing is for rich people. No conspiracy theories here - I believe it's a natural consequence of laws that are intended to protect investors - but that doesn't make it any less frustrating for me. Logistics aside, Jane and I would love to raise money from everyday people like ourselves. Unfortunately, exemptions from securities registration (which we can't afford to not qualify for) exist primarily for these types of scenarios:

-Unlimited number of accredited investors. For the most part, accredited investors are people with net worths over $1M and/or who earn over $200K a year.

-X or fewer non-accredited investors. X = 25 for Wisconsin, which (and this is total BS) includes out-of-state investors. This means that if you need to raise $750K, each investor would need to contribute an average of $30K.

-Private offerings only. If this post implied that I was offering you a share of RePublic equity, I'd already be disqualified from this type of exemption.

Now you know something that most introductory business guides don't tell you.

Saturday, October 18, 2008

Army of Experts

Before I talk about us, let's talk about them. Regarding the bailout bill, from the Wisconsin Restaurant Association:

As a result of the restaurant industry’s presence on Capitol Hill during these historical proceedings, one of the restaurant industry’s key agenda items was included in the bailout bill. Depreciation for restaurant construction and improvements was accelerated from 39 1/2 years down to 15 years.

I hate that @#$%. Yes, changing the depreciation schedule is good for the restaurant industry. No, the change doesn't hurt anyone else. Yes, I know that sidestepping the legislative process is Standard Operating Procedure for Congress and that people need to play the game to get things done. The loophole works both ways, though - Team Evil is equally capable of attaching unrelated contingents to bills that require urgent passage. That's how Wisconsin's idiotic Brewpub Tourism Development Act got passed last year. I hope the craft brewing community continues to beat that dead horse until brewing companies like Goose Island and Dogfish Head can legally exist in Wisconsin once again. I want that dead horse on television. How awesome would a New Glarus beer hall be, all serving cheese and sausage platters on the grounds of their new production facility?

Anyway, I have a Private Placement Memorandum (PPM) written and I'm scheduled to meet with a lawyer next week. I don't know if writing the document myself will make life easier or harder on lawyers, but at least Jane and I will have options. The big reason for seeking legal advice is to determine how our capital needs and various investment-solicitation strategies will affect which securities registration exemptions we'll qualify for. The following week, we'll be meeting with the city's Office of Business Resources to outline the city's involvement in our project. Our business plan's proposed timeline is pretty sad, so hopefully the city will help us straighten it out a bit.

As a result of the restaurant industry’s presence on Capitol Hill during these historical proceedings, one of the restaurant industry’s key agenda items was included in the bailout bill. Depreciation for restaurant construction and improvements was accelerated from 39 1/2 years down to 15 years.

I hate that @#$%. Yes, changing the depreciation schedule is good for the restaurant industry. No, the change doesn't hurt anyone else. Yes, I know that sidestepping the legislative process is Standard Operating Procedure for Congress and that people need to play the game to get things done. The loophole works both ways, though - Team Evil is equally capable of attaching unrelated contingents to bills that require urgent passage. That's how Wisconsin's idiotic Brewpub Tourism Development Act got passed last year. I hope the craft brewing community continues to beat that dead horse until brewing companies like Goose Island and Dogfish Head can legally exist in Wisconsin once again. I want that dead horse on television. How awesome would a New Glarus beer hall be, all serving cheese and sausage platters on the grounds of their new production facility?

Anyway, I have a Private Placement Memorandum (PPM) written and I'm scheduled to meet with a lawyer next week. I don't know if writing the document myself will make life easier or harder on lawyers, but at least Jane and I will have options. The big reason for seeking legal advice is to determine how our capital needs and various investment-solicitation strategies will affect which securities registration exemptions we'll qualify for. The following week, we'll be meeting with the city's Office of Business Resources to outline the city's involvement in our project. Our business plan's proposed timeline is pretty sad, so hopefully the city will help us straighten it out a bit.

Wednesday, October 8, 2008

Burlington Northern Pulling Out of the World

Our business plan is ready to shop around! We still have a small amount of revising to do, but I don't expect that to change as the fundraising process generates feedback. Jane is taking over the business plan tweaks while I assemble an investment offering. I use the word 'assemble' instead of 'write' because I'll be stealing most of its content from the investment documents of two other breweries.

I haven't bought any hops yet, primarily because most of the ones for sale were grown in 2007. Brewers are selling off their old stashes while the 2008 crop comes in. Properly stored year-old hops would be fine if I needed them right now, but I don't want to be using them next summer. I met with James from Gorst Valley Hops a couple of weeks ago, and it looks promising that I'll be able to buy all of my citrusy American hops from him next fall. At the risk of digressing, he's a horticulturist who's more interested in turning Wisconsin farmers onto hop growing than he is in growing them himself. His main reasons for growing them right now are to prove their worth and to test a mobile processing facility that he's building. It was pretty awesome to show him my beer list and hear him say "I can get you that" almost every time I mentioned a weird ingredient. He even knows some used equipment dealers.

It's been a while since I talked about pilot brewing. First off, my beer fridge is working again! A sloppy moisture control vs. energy efficiency switch is a much better problem to have than a fridge that's actually broken. 'Nuff said. The second mint porter tasted awesome, except when I drank it too cold. Low temperature gave it an unpleasant shaprness - I still believe a hop/mint interaction is involved, and I'll name CO2 as a suspect as well - but the beer is basically a dessert at "cool but not cold" temperatures. Despite it's warm leanings, the beer made an excellent custard float. Much better than the first batch. Reducing the beer on the stove to use as a syrup, however, did not taste good. Holy bitterness! Although I reduced the hops dramatically, the beer wasn't too sweet. I suspect the mint lends its own bitterness, which balances malt sweetness in a similar manner as hops. Next time, I'm gonna brew the beer with no hops whatsoever. I transfered the maple farmhouse ale into its serving keg on Monday, which tasted very nice in its uncarbonated state. I have a batch of pale ale in bottles as well, which will be given away at a Locksley after-party this Friday, and I brewed a batch of Belgian pumpkin ale last week for my brother's wedding. That's about it for now!

I haven't bought any hops yet, primarily because most of the ones for sale were grown in 2007. Brewers are selling off their old stashes while the 2008 crop comes in. Properly stored year-old hops would be fine if I needed them right now, but I don't want to be using them next summer. I met with James from Gorst Valley Hops a couple of weeks ago, and it looks promising that I'll be able to buy all of my citrusy American hops from him next fall. At the risk of digressing, he's a horticulturist who's more interested in turning Wisconsin farmers onto hop growing than he is in growing them himself. His main reasons for growing them right now are to prove their worth and to test a mobile processing facility that he's building. It was pretty awesome to show him my beer list and hear him say "I can get you that" almost every time I mentioned a weird ingredient. He even knows some used equipment dealers.

It's been a while since I talked about pilot brewing. First off, my beer fridge is working again! A sloppy moisture control vs. energy efficiency switch is a much better problem to have than a fridge that's actually broken. 'Nuff said. The second mint porter tasted awesome, except when I drank it too cold. Low temperature gave it an unpleasant shaprness - I still believe a hop/mint interaction is involved, and I'll name CO2 as a suspect as well - but the beer is basically a dessert at "cool but not cold" temperatures. Despite it's warm leanings, the beer made an excellent custard float. Much better than the first batch. Reducing the beer on the stove to use as a syrup, however, did not taste good. Holy bitterness! Although I reduced the hops dramatically, the beer wasn't too sweet. I suspect the mint lends its own bitterness, which balances malt sweetness in a similar manner as hops. Next time, I'm gonna brew the beer with no hops whatsoever. I transfered the maple farmhouse ale into its serving keg on Monday, which tasted very nice in its uncarbonated state. I have a batch of pale ale in bottles as well, which will be given away at a Locksley after-party this Friday, and I brewed a batch of Belgian pumpkin ale last week for my brother's wedding. That's about it for now!

Sunday, September 28, 2008

No Accountability!

I'm done with weekly accountability updates. The whole purpose of them was to keep me on track, which they aren't doing. This weblog is becoming tedious, and people who try to use it as a business resource will have a lot of useless crap to wade through from late June to late September. Setting frequent goals and reflecting on my progress is important, but the boredom of it shouldn't be yours to bear.

Wednesday, September 24, 2008

Da Beers

I mentioned in my last post that I made all of my beer recipes for a year. We're probably going to start with eight taps, which will prevent individual batches from being served for too long. We'll likely have four year-round, two seasonal and two rotating beers on tap at any given time. Behold, the preliminary beer list!

Year-Round:

House Ale - the signature session beer of RePublic!

Belgian Blond

Pale Ale - we'll name it Heartattack and Bine if Tom Waits doesn't sue us.

Chocolate Porter

Spring/Summer:

Ordinary Bitter

Summer Pils

Fall/Winter:

Scottish Heavy - the name is misleading; it's a session beer.

Belgian Pumpkin - a Squashed Stereotype, if you will.

Rotating:

Grapefruit Lager - a light lager spiced with grapefruit zest.

Wildflower Belgian Pale - a restrained Belgian ale brewed with wildflower honey.

Cardamom Coffee Stout - thanks, Kevin, for the Arabic coffee idea.

Maple Biere de Garde - a farmhouse ale with unrefined Maple syrup.

Old Ale - a blend of fresh beer and stock ale that's been inoculated with Brettanomyces and aged in wine barrels.

Grand Cru, aka the Raspberry Belgianwine.

Imperial Black Lager - aged for a year before serving. Will I get dork points for naming it Gestahl's?

I'd love to brew a doppelbock, but mostly because I want to name it Lowest Common Denominator. I can't really see a doppelbock working as a pub beer, but don't rule it out.

Year-Round:

House Ale - the signature session beer of RePublic!

Belgian Blond

Pale Ale - we'll name it Heartattack and Bine if Tom Waits doesn't sue us.

Chocolate Porter

Spring/Summer:

Ordinary Bitter

Summer Pils

Fall/Winter:

Scottish Heavy - the name is misleading; it's a session beer.

Belgian Pumpkin - a Squashed Stereotype, if you will.

Rotating:

Grapefruit Lager - a light lager spiced with grapefruit zest.

Wildflower Belgian Pale - a restrained Belgian ale brewed with wildflower honey.

Cardamom Coffee Stout - thanks, Kevin, for the Arabic coffee idea.

Maple Biere de Garde - a farmhouse ale with unrefined Maple syrup.

Old Ale - a blend of fresh beer and stock ale that's been inoculated with Brettanomyces and aged in wine barrels.

Grand Cru, aka the Raspberry Belgianwine.

Imperial Black Lager - aged for a year before serving. Will I get dork points for naming it Gestahl's?

I'd love to brew a doppelbock, but mostly because I want to name it Lowest Common Denominator. I can't really see a doppelbock working as a pub beer, but don't rule it out.

Friday, September 19, 2008

Backtracking

Time that I spent updating the business plan this week: about six hours.

My deviation started on Monday, when I spent way too much time preparing cost estimates for another commercial brewer. It makes me happy that he thinks my work is thorough enough to apply to his real-world situation, but I should have gotten it done over the weekend.

I did rewrite some of the business plan on Tuesday. That afternoon, I met with an interested homebrewer to give him the lowdown on the project. He raised a lot of issues that'll be better to address now than later. The biggest is that our startup cost is going to be a turn-off to potential investors. That's what I get for thinking "I'll ask for enough to buy all new equipment, then buy as much used gear as I can and return the difference." To an investor, a 1.5-to-1 ratio of annual sales to initial capital may be acceptable but a 1-to-1 ratio may not. I'd been feeling guilty about my generalized startup costs anyway, so I dusted off the old itemized equipment list and gave it a makeover. At first, I wanted to find pieces of used equipment and plug their prices into the list. After a few hours, I realized it would take me years to estimate my costs that way. What I did instead was assume that used equipment will cost 40% of new and that I'll be able to find 50% of my equipment used, which means my expected equipment cost is 70% of all-new. There you have it: our first official business gamble.

Updating the equipment costs didn't take up very much time, but creating an entire year worth of beer recipes did. Why would I do something like that? To figure out my hop needs, silly! It's harvest time and there seem to be some hops available on the spot market (meaning they're not all going to fulfill prior contracts). A while back, New Zealand Hops told me that my chances of getting hops next spring are decent. They even thought that I could get organic hops, which is unheard of these days. The problem is that the hops in New Zealand aren't harvested until March, so I won't know where I truly stand until then - I'm still waiting for them to project their yield and give me a prediction. If I can get my grubby little hands on some hops now, I'm absolutely going to do it. If I don't and New Zealand fails to come through for me (never!), I hope you like guest beers.

Looking a little ways down the road, a future brewery owner who I met at the Craft Brewers Conference was awesome enough to send me his private placement memorandum. My legal paranoia dictates that he'll have to remain anonymous for the time being, but that document is going to be a monster help. Once the business plan is ready to shop around, I'll tailor the document for our needs and have a lawyer review it. Paying a lawyer to write one from scratch would probably cost over ten grand.

Pilot brewing continues, I still need a beer fridge, blah blah blah.

My deviation started on Monday, when I spent way too much time preparing cost estimates for another commercial brewer. It makes me happy that he thinks my work is thorough enough to apply to his real-world situation, but I should have gotten it done over the weekend.

I did rewrite some of the business plan on Tuesday. That afternoon, I met with an interested homebrewer to give him the lowdown on the project. He raised a lot of issues that'll be better to address now than later. The biggest is that our startup cost is going to be a turn-off to potential investors. That's what I get for thinking "I'll ask for enough to buy all new equipment, then buy as much used gear as I can and return the difference." To an investor, a 1.5-to-1 ratio of annual sales to initial capital may be acceptable but a 1-to-1 ratio may not. I'd been feeling guilty about my generalized startup costs anyway, so I dusted off the old itemized equipment list and gave it a makeover. At first, I wanted to find pieces of used equipment and plug their prices into the list. After a few hours, I realized it would take me years to estimate my costs that way. What I did instead was assume that used equipment will cost 40% of new and that I'll be able to find 50% of my equipment used, which means my expected equipment cost is 70% of all-new. There you have it: our first official business gamble.

Updating the equipment costs didn't take up very much time, but creating an entire year worth of beer recipes did. Why would I do something like that? To figure out my hop needs, silly! It's harvest time and there seem to be some hops available on the spot market (meaning they're not all going to fulfill prior contracts). A while back, New Zealand Hops told me that my chances of getting hops next spring are decent. They even thought that I could get organic hops, which is unheard of these days. The problem is that the hops in New Zealand aren't harvested until March, so I won't know where I truly stand until then - I'm still waiting for them to project their yield and give me a prediction. If I can get my grubby little hands on some hops now, I'm absolutely going to do it. If I don't and New Zealand fails to come through for me (never!), I hope you like guest beers.

Looking a little ways down the road, a future brewery owner who I met at the Craft Brewers Conference was awesome enough to send me his private placement memorandum. My legal paranoia dictates that he'll have to remain anonymous for the time being, but that document is going to be a monster help. Once the business plan is ready to shop around, I'll tailor the document for our needs and have a lawyer review it. Paying a lawyer to write one from scratch would probably cost over ten grand.

Pilot brewing continues, I still need a beer fridge, blah blah blah.

Sunday, September 14, 2008

Logistics, Shmogistics

Madison Sourdough will sell us partially-baked loaves for slightly more than it would cost us to hire one full-time baker. We don't need to quantify ingredient costs, energy costs, staff scheduling and owner inexperience to realize the decision is a no-brainer. Randy George, you were right! I hadn't even thought of partially-baked loaves: freezing them until we need them will reduce waste and allow us to customize a delivery schedule, and the pub will still be filled with delicious bakery smells.

I spent all day yesterday at the Master Brewers Association of the Americas' Midwest Technical Conference. The event was very informative, relatively affordable (I don't have enough time right now to rant about the American Society of Brewing Chemists) and a lot of fun. As usual, I drank a healthy amount of beer and met a lot of cool people. The price of admission included a tour of New Glarus's amazing new brewery and dinner at J.T. Whitney's. I'm glad that I spent the day learning things instead of watching Michigan lose to Notre Dame. It's not gonna be my year for football.

I'm back in business plan mode. By the end of next week, I want to have the plan ready to show potential investors. Jane and I will need to do other things before we actually can, such as write a formal investment offering and make sure that we won't be breaking any laws, but we'll try to not climb those mountains before our gear is packed.

I spent all day yesterday at the Master Brewers Association of the Americas' Midwest Technical Conference. The event was very informative, relatively affordable (I don't have enough time right now to rant about the American Society of Brewing Chemists) and a lot of fun. As usual, I drank a healthy amount of beer and met a lot of cool people. The price of admission included a tour of New Glarus's amazing new brewery and dinner at J.T. Whitney's. I'm glad that I spent the day learning things instead of watching Michigan lose to Notre Dame. It's not gonna be my year for football.

I'm back in business plan mode. By the end of next week, I want to have the plan ready to show potential investors. Jane and I will need to do other things before we actually can, such as write a formal investment offering and make sure that we won't be breaking any laws, but we'll try to not climb those mountains before our gear is packed.

Sunday, September 7, 2008

Anniversary Beer

In May of 2006, I brewed a beer that's known around the house as Raspberry Belgianwine. Once a year - on our wedding anniversary - Rachel and I share a champagne bottle of it. The base beer was essentially a 5-gallon batch of "imperialized" tripel. After a couple weeks of fermentation, I added 4 lbs of raspberries and a peeled vanilla bean. The beer weighs in at 10% abv. Here's what it looked like after 4 years of marriage:

So far, the beer has tasted better every year. If the trend continues, Rachel and I will be drinking the delicious final bottle on our 13th anniversary. Brewing the beer at the pub will require a coarse filter to fully separate the beer from the fruit. It'll also cost me about $160 per keg (half-barrel) to brew, unless I can find organic raspberries for cheaper than $4.00/lb. Money and hassle, pssht. This beer WILL be brewed for commercial consumption!

In other news, it turns out that Jane only spent a week in the UK. I finished the bakery book well before she got back, but I'm still giving myself another week to research bakery logistics.

So far, the beer has tasted better every year. If the trend continues, Rachel and I will be drinking the delicious final bottle on our 13th anniversary. Brewing the beer at the pub will require a coarse filter to fully separate the beer from the fruit. It'll also cost me about $160 per keg (half-barrel) to brew, unless I can find organic raspberries for cheaper than $4.00/lb. Money and hassle, pssht. This beer WILL be brewed for commercial consumption!

In other news, it turns out that Jane only spent a week in the UK. I finished the bakery book well before she got back, but I'm still giving myself another week to research bakery logistics.

Sunday, August 31, 2008

Hash Browns

Brewing and cooking have a lot in common. My process for making hash browns at home goes something like this:

-Peel a bunch of potatoes.

-Shred the peeled potatoes into a strainer.

-Place the strainer into a huge bowl and fill with water.

-Allow the potatoes to soak for a couple of hours.

-Remove the strainer and briefly rinse the potatoes.

-Dump the bowl water and put the strainer in the bowl.

-Set the bowl in the fridge and let sit overnight.

-Pan fry the potatoes in an elaborate ritual involving oil, onions, seasoned salt and pepper.

During the soak, a bunch of white powder falls through the strainer and settles at the bottom of the bowl. The brewing angle: how much of the white stuff is potato starch and how much of it is precipitated calcium carbonate from the water reaching equilibrium with atmospheric carbon dioxide? Hmmm...

-Peel a bunch of potatoes.

-Shred the peeled potatoes into a strainer.

-Place the strainer into a huge bowl and fill with water.

-Allow the potatoes to soak for a couple of hours.

-Remove the strainer and briefly rinse the potatoes.

-Dump the bowl water and put the strainer in the bowl.

-Set the bowl in the fridge and let sit overnight.

-Pan fry the potatoes in an elaborate ritual involving oil, onions, seasoned salt and pepper.

During the soak, a bunch of white powder falls through the strainer and settles at the bottom of the bowl. The brewing angle: how much of the white stuff is potato starch and how much of it is precipitated calcium carbonate from the water reaching equilibrium with atmospheric carbon dioxide? Hmmm...

Saturday, August 30, 2008

Important Note:

Jane is doing very important research on cask ales in England right now. This requires many visits to many pubs and many many taste tests. Gathering of important scientific data, you know.

Business Banking

Did you know that business checking accounts have monthly fees? We didn't! I'd heard good things about Johnson Bank, so Jane and I talked with them about opening an account. The woman we met was extremely nice and very honest, which was awesome. She recommended that we open a money market account to hold investments until we're ready to make a lot of withdrawals, but not do so until we check out some other banks first. She admitted that bars and restaurants aren't Johnson's strong suit, emphasized how important location will be in choosing a bank (daily deposits once we're up and running), and even recommended a few banks for us to talk with. Given that my research of the restaurant industry has gone mostly as follows,

Restaurant industry: give me $500 and I'll give you a tiny clue towards solving this one problem.

Me: that's not much incentive for me to put some clothes on and leave the forest.

talking with Johnson Bank was pretty refreshing. We didn't open a checking account, but the process didn't happen without progress. Having an IRS Employer Identification Number is required to open a business checking account, so we got one.

We didn't make a hard decision on having a bakery, but we're going to proceed as though we chose 'yes'. I'm halfway through a surprisingly good book about opening a bakery, and I'm just getting to the chapters on equipment and space requirements. Those plus ingredient, labor and energy costs will give us the foundation of making a feasibility decision. I did some work on updating the business plan to include a bakery, but I still have a ways to go.

Jane will be out of town for a couple of weeks, so I'm flying solo. My plan is to finish the book and work on the logistics of a bakery-focused menu. I'll be trying to answer questions like "how much do ingredients cost? How will we transform bulk purchases into individual portions? What will our prices be? What equipment will be required for each step? How much space will it take up? How much can we expect to sell each day? How many employees will that require?" If I can get that done by the time Jane gets back, I'll be pretty excited.

The latest pilot batch is a biere de garde with maple syrup. I fermented the beer at cool temperatures with a blend of Saison Dupont yeast and a neutral American ale yeast, then warmed it up as fermentation began to slow. My goal is to keep the saison character subtle while fermenting as much of the sugar as possible. Jeff brewed the beer with me last Saturday and it's still fermenting away, which is a full 2-3 days after fermentation usually stops. My plan just might work, mwahaha!

Restaurant industry: give me $500 and I'll give you a tiny clue towards solving this one problem.

Me: that's not much incentive for me to put some clothes on and leave the forest.

talking with Johnson Bank was pretty refreshing. We didn't open a checking account, but the process didn't happen without progress. Having an IRS Employer Identification Number is required to open a business checking account, so we got one.

We didn't make a hard decision on having a bakery, but we're going to proceed as though we chose 'yes'. I'm halfway through a surprisingly good book about opening a bakery, and I'm just getting to the chapters on equipment and space requirements. Those plus ingredient, labor and energy costs will give us the foundation of making a feasibility decision. I did some work on updating the business plan to include a bakery, but I still have a ways to go.

Jane will be out of town for a couple of weeks, so I'm flying solo. My plan is to finish the book and work on the logistics of a bakery-focused menu. I'll be trying to answer questions like "how much do ingredients cost? How will we transform bulk purchases into individual portions? What will our prices be? What equipment will be required for each step? How much space will it take up? How much can we expect to sell each day? How many employees will that require?" If I can get that done by the time Jane gets back, I'll be pretty excited.

The latest pilot batch is a biere de garde with maple syrup. I fermented the beer at cool temperatures with a blend of Saison Dupont yeast and a neutral American ale yeast, then warmed it up as fermentation began to slow. My goal is to keep the saison character subtle while fermenting as much of the sugar as possible. Jeff brewed the beer with me last Saturday and it's still fermenting away, which is a full 2-3 days after fermentation usually stops. My plan just might work, mwahaha!

Sunday, August 24, 2008

Death of a Beer Fridge

My second (as in consecutive) beer fridge died last night. The light still works, but none of the moving parts turn on. I unplugged the fridge for a few hours to see if the compressor just overheated, but its status remains unchanged. I'm starting to feel like someone who keeps replacing dead pet fish instead of learning how to care for them properly. Putting fridges outside and calling the salvage company is going to become a mundane routine instead of something I'm slightly uncomfortable doing. The people who come to haul the fridges away, who I'll eventually know on a first-name basis, won't drink coffee in the morning because they'll know that I'll have some waiting.

Jane and I made a preliminary menu and outlined some of the wine types we'd like to serve last week. We decided that "full bar" is a sufficient business plan description for the spirits. It sounds like available wines change all the time, so saying "our five wines will be blah blah blah" would be silly. We also signed the operating agreement, so RePublic is more official than ever. Amidst the business plan revision, we need to open a bank account. I'm going to go ahead and make that a goal for next week, even though Jane is skipping town on Thursday for a couple of weeks.

We didn't get much farther on researching a bakery, although Tristan told us that baking is heavily influenced by the weather and Wisconsin doesn't have a very good climate for it. At least the playing field is even for local bakers.

Here's the official to-do list for next week:

-Open a bank account.

-Decide yes or no on a bakery.

-Strengthen the descriptions of kitchen and bar operations in the business plan.

That's all folks! If you're trying to get rid of a fridge with at least a 24"x24"x30" (WxDxH) cube of space - or know how to repair refrigerators and will do it for less than the cost of a cheap used fridge - let me know.

Jane and I made a preliminary menu and outlined some of the wine types we'd like to serve last week. We decided that "full bar" is a sufficient business plan description for the spirits. It sounds like available wines change all the time, so saying "our five wines will be blah blah blah" would be silly. We also signed the operating agreement, so RePublic is more official than ever. Amidst the business plan revision, we need to open a bank account. I'm going to go ahead and make that a goal for next week, even though Jane is skipping town on Thursday for a couple of weeks.

We didn't get much farther on researching a bakery, although Tristan told us that baking is heavily influenced by the weather and Wisconsin doesn't have a very good climate for it. At least the playing field is even for local bakers.

Here's the official to-do list for next week:

-Open a bank account.

-Decide yes or no on a bakery.

-Strengthen the descriptions of kitchen and bar operations in the business plan.

That's all folks! If you're trying to get rid of a fridge with at least a 24"x24"x30" (WxDxH) cube of space - or know how to repair refrigerators and will do it for less than the cost of a cheap used fridge - let me know.

Tuesday, August 19, 2008

File Sharing Season Finale

I snuck some files onto Napster RePublic when you weren't looking, including a big one: our financial projections. Note that the file doesn't say "give us money" anywhere, so all you securities lawyers can still be our friends.

Saturday, August 16, 2008

Giant Update, All

Last week was pretty busy. Here's what we did:

-Served an altbier at the pre-Great Taste brewers' dinner.

-Finalized the operating agreement.

-Discussed our plans with Peter of Potter's Crackers.

-Talked with a couple of bakers about baking our own bread.

-Brewed batch #2 of mint porter.

-Finished the rough draft of the business plan.

The altbier turned out decently. The beer was clean and crisply bitter, but I was disappointed in its malt character. When creating recipes, brewers will often use ingredients from each beer's region of origin. For example, German-made malts are typically used to brew Oktoberfests. However, the game changes when you want to use organic ingredients and not be a hypocrite by shipping thousands of pounds of malt halfway around the globe each year. For my pilot batches, I've used entirely Briess malts from nearby Chilton, WI. In general, their malts are clean-flavored and perform well in the brewhouse. So far they've been great for beers where other ingredients provide the dominant flavors, such as pale ales (hops) and Belgian ales (yeast). For beers where malt flavors are the highlight, though, I find them lacking in complexity. A large part of the problem would be solved if Briess produced organic versions of their Pilsen, pale ale and black malts. I may be giving Briess an unfair rap because their malts' subtleties might be overwhelmed by unwanted esters - it's much harder to control fermentation temperature in a home brewery than a commercial brewery. Still, it'll be pretty telling if I see better results with the international malts that I'm about to start using.

A couple months ago (I think), Peter sent me an email saying he was interested in our project and available to talk. I took him up on his offer and he gave me a lot of really good advice. I wanted to introduce him to Jane, so we met again last week. One thing he said was that he'd love to see a brewpub with a menu of light food built around an on-premise bakery. After he left, Jane and I were like "hmmm..." I'd heard that baking is very difficult in a restaurant setting, but our pub won't be a full-blown restaurant. Picture baguettes served with things like garlic butter, cheeses, fruits and sausages. Maybe some sandwiches with veggies or shaved beef and gravy. Whether we hire a baker or buy bread from a local bakery, or whether we use bread as the focus of our menu or simply as a component, I like the idea a lot.

I talked with a couple of bakers last week: Jeff Renner from Ann Arbor, MI and Randy George from Red Hen Baking Co. Jeff bakes small batches of bread in a bakery attached to his house, and is also a well-known homebrewer. Unfortunately, I never got to taste his bread while I lived in Michigan. Randy kept me fed in Vermont with the best bread I've ever eaten: my weekend ritual was to eat half of a seeded baguette with cheese and a pear, then turn the other half into two pizzas (and sometimes turn the pizzas into a delicious grinder). Both people gave me a lot of good advice, but Randy is concerned that we won't be making enough bread to justify building a bakery. We're still talking via email and I'm really interested in what else he'll have to say.

Mint porter #2 has about twice as much mint, 1/4 as much hops and about 1/3 more specialty malt than batch #1. I added the mint earlier in the boil and the beer tasted pretty good out of the kettle, which is rare. It was very dessert-like. This batch is going into bottles instead of a keg because I'm going to give a case to Matt, the aspiring hop grower we met last month. I think it's funny that he'll be getting a beer with almost no hops in it, but his girlfriend - a professional baker, mwahaha - wanted something dark to go with a rye bread.

I don't want to talk about the business plan. The rough draft is done, but we need to do a lot more research to clean it up. Industry numbers are nice for making financial projections, but writing the plan made me realize that we don't really have a plan for anything besides the beer. What kinds of food and other beverages will we serve? What will the place look and feel like? How will we hire, train and retain employees? What exactly is the competitive landscape we'll be entering, and how will we fit into it? How will we say things that we know intuitively - e.g. organic beer is a good fit for neighborhood X - without resorting to stereotypes? I'm feeling sort of overwhelmed, but I'm happy with the progress we've made in the last week.

To do next week:

-Continue to research baking logistics.

-Define a preliminary menu, wine list and bar inventory.

-Print and sign the operating agreement.

-Served an altbier at the pre-Great Taste brewers' dinner.

-Finalized the operating agreement.

-Discussed our plans with Peter of Potter's Crackers.

-Talked with a couple of bakers about baking our own bread.

-Brewed batch #2 of mint porter.

-Finished the rough draft of the business plan.

The altbier turned out decently. The beer was clean and crisply bitter, but I was disappointed in its malt character. When creating recipes, brewers will often use ingredients from each beer's region of origin. For example, German-made malts are typically used to brew Oktoberfests. However, the game changes when you want to use organic ingredients and not be a hypocrite by shipping thousands of pounds of malt halfway around the globe each year. For my pilot batches, I've used entirely Briess malts from nearby Chilton, WI. In general, their malts are clean-flavored and perform well in the brewhouse. So far they've been great for beers where other ingredients provide the dominant flavors, such as pale ales (hops) and Belgian ales (yeast). For beers where malt flavors are the highlight, though, I find them lacking in complexity. A large part of the problem would be solved if Briess produced organic versions of their Pilsen, pale ale and black malts. I may be giving Briess an unfair rap because their malts' subtleties might be overwhelmed by unwanted esters - it's much harder to control fermentation temperature in a home brewery than a commercial brewery. Still, it'll be pretty telling if I see better results with the international malts that I'm about to start using.

A couple months ago (I think), Peter sent me an email saying he was interested in our project and available to talk. I took him up on his offer and he gave me a lot of really good advice. I wanted to introduce him to Jane, so we met again last week. One thing he said was that he'd love to see a brewpub with a menu of light food built around an on-premise bakery. After he left, Jane and I were like "hmmm..." I'd heard that baking is very difficult in a restaurant setting, but our pub won't be a full-blown restaurant. Picture baguettes served with things like garlic butter, cheeses, fruits and sausages. Maybe some sandwiches with veggies or shaved beef and gravy. Whether we hire a baker or buy bread from a local bakery, or whether we use bread as the focus of our menu or simply as a component, I like the idea a lot.

I talked with a couple of bakers last week: Jeff Renner from Ann Arbor, MI and Randy George from Red Hen Baking Co. Jeff bakes small batches of bread in a bakery attached to his house, and is also a well-known homebrewer. Unfortunately, I never got to taste his bread while I lived in Michigan. Randy kept me fed in Vermont with the best bread I've ever eaten: my weekend ritual was to eat half of a seeded baguette with cheese and a pear, then turn the other half into two pizzas (and sometimes turn the pizzas into a delicious grinder). Both people gave me a lot of good advice, but Randy is concerned that we won't be making enough bread to justify building a bakery. We're still talking via email and I'm really interested in what else he'll have to say.

Mint porter #2 has about twice as much mint, 1/4 as much hops and about 1/3 more specialty malt than batch #1. I added the mint earlier in the boil and the beer tasted pretty good out of the kettle, which is rare. It was very dessert-like. This batch is going into bottles instead of a keg because I'm going to give a case to Matt, the aspiring hop grower we met last month. I think it's funny that he'll be getting a beer with almost no hops in it, but his girlfriend - a professional baker, mwahaha - wanted something dark to go with a rye bread.

I don't want to talk about the business plan. The rough draft is done, but we need to do a lot more research to clean it up. Industry numbers are nice for making financial projections, but writing the plan made me realize that we don't really have a plan for anything besides the beer. What kinds of food and other beverages will we serve? What will the place look and feel like? How will we hire, train and retain employees? What exactly is the competitive landscape we'll be entering, and how will we fit into it? How will we say things that we know intuitively - e.g. organic beer is a good fit for neighborhood X - without resorting to stereotypes? I'm feeling sort of overwhelmed, but I'm happy with the progress we've made in the last week.

To do next week:

-Continue to research baking logistics.

-Define a preliminary menu, wine list and bar inventory.

-Print and sign the operating agreement.

Wednesday, August 6, 2008

Vacation

In a prior update, I said something like "water chemistry will consume me if I work on it outside of lunch." I should have said "water chemistry will consume me if I work on it at all." It needed to be done eventually, but obsessing over it last week was poor prioritizing. The good news is that I'm done with it, and I even fixed the phosphoric acid calculations. As usual, updates are on The Taped Plastic Glasses Fan Club Homepage. The bad news is that I didn't do much with the business plan. A wholesale lack of discipline isn't my only excuse: I had to deal with a shattered car window as well. Jeff finished the operating agreement, and he's waiting for the final stamp of approval from me and Jane.

Today is the only day that I'm in the office. Rachel and I spent last weekend camping and watching Radiohead with my brother and his fiancee. The show was excellent, and we drove home from Ohio yesterday. I'll be spending the rest of the week with my friend Destiny. She's a brewer at Otter Creek, was responsible for most of my social life in Vermont, and has never been to the Great Taste. I'll be back at work on Tuesday and hope to catch up on the business plan by the end of next week.

Today is the only day that I'm in the office. Rachel and I spent last weekend camping and watching Radiohead with my brother and his fiancee. The show was excellent, and we drove home from Ohio yesterday. I'll be spending the rest of the week with my friend Destiny. She's a brewer at Otter Creek, was responsible for most of my social life in Vermont, and has never been to the Great Taste. I'll be back at work on Tuesday and hope to catch up on the business plan by the end of next week.

Wednesday, July 30, 2008

Slaked Lime

With all of the cold aging going on in my beer fridge, I haven't been brewing much beer lately. I put an end to that troubling trend this morning and whipped out a batch of amber ale that should quench the late summer heat in a flavorful way. I usually dose my brewing water with lactic acid to hit my target mash pH, but I tried something different today: slaked lime. A big thanks to fellow homebrewers and MHTG members Ted Gisske and Mark Garthwaite for turning me on to the idea. I'd heard about the process before, but didn't pay much attention to it because I assumed that Madison's water didn't have enough calcium to make it worthwhile. Not true! Basically, slaked lime reduces residual alkalinity by causing calcium and bicarbonate to form chalk and precipitate out of solution. The reaction will occur on its own as carbon dioxide in the water and air reach equilibrium, but it happens at the speed of my grandpa driving. Slaked lime speeds up the process to a "let the water sit overnight" rate. Before adding the lime, I added some extra calcium to the water via gypsum and calcium chloride. The process worked really well, but the big test will come in three weeks when the beer will be ready to drink. If you brew your own beer and want to give slaked lime a try, you can find it labeled as "pickling lime" in the canning supplies section of Woodman's. I added some usage calculations to the files at Geek Central as well.

Sunday, July 27, 2008

Halfway Home

It's business as usual on the business plan. I gave myself two weeks to finish a rough draft and I'd wager that I'm over halfway done. On tap this week:

-Finish the rough draft of the business plan.

-Meet with our lawyer to wrap up the operating agreement. Yup, our attorney is none other than Jeff from Madison Beer Review. I finally remembered to ask him if it's OK that we disclose said information.

-Brew an amber ale and order some ingredients for future batches.

Water chemistry! Excess alkalinity results in poor extraction efficiency (the "mileage" of malted barley) and harsh astringency. When malt and hot water are mixed, calcium and magnesium help combat alkalinity. For most beer styles, Madison's water has more alkalinity than its calcium and magnesium can handle. One method of reducing alkalinity is to add a food-grade acid to the water. Lactic and phosphoric acids are popular among brewers because they naturally exist in beer. I recently learned that phosphoric acid removes calcium from water. I can't quantify the amount, but calcium removal is usually not a good thing for brewers. Figuring out the specifics is way beyond my scope of chemistry knowledge, but I'm not going to let that stop me. I can't work on it during work hours because it'll completely consume me, but I might chip away at it during lunch breaks. How Poindexter is that? If you downloaded my water chemistry spreadsheet, ignore the part about phosphoric acid because it's horribly wrong.

-Finish the rough draft of the business plan.

-Meet with our lawyer to wrap up the operating agreement. Yup, our attorney is none other than Jeff from Madison Beer Review. I finally remembered to ask him if it's OK that we disclose said information.

-Brew an amber ale and order some ingredients for future batches.

Water chemistry! Excess alkalinity results in poor extraction efficiency (the "mileage" of malted barley) and harsh astringency. When malt and hot water are mixed, calcium and magnesium help combat alkalinity. For most beer styles, Madison's water has more alkalinity than its calcium and magnesium can handle. One method of reducing alkalinity is to add a food-grade acid to the water. Lactic and phosphoric acids are popular among brewers because they naturally exist in beer. I recently learned that phosphoric acid removes calcium from water. I can't quantify the amount, but calcium removal is usually not a good thing for brewers. Figuring out the specifics is way beyond my scope of chemistry knowledge, but I'm not going to let that stop me. I can't work on it during work hours because it'll completely consume me, but I might chip away at it during lunch breaks. How Poindexter is that? If you downloaded my water chemistry spreadsheet, ignore the part about phosphoric acid because it's horribly wrong.

Saturday, July 19, 2008

Saturday, Saturday

It turns out that I was too ambitious last week. I deviated by about 4 hours to work on water chemistry calculations, but spent the rest of the week working on my scheduled to-do list.

On the business plan front (it's kind of like a war), I installed the numbers and wrote the product descriptions. Communicating math in concise English was a lot more difficult than I expected. In addition, I kept writing things like "most brewpubs do blah blah blah" and realizing "I have no idea if that's true." As a result, I spent a lot of time doing additional research to back up my claims. I expect that trend to continue as I make my way into less familiar territory, such as the marketing plan. From here out, I'm giving myself two weeks to finish a rough draft of the business plan.

Jane and I met to review the operating plan and told our lawyer what we think. We're very close to being done.

Creme de Menthe, mixed into Edmund Fitzgerald Porter at 1/4 tsp per 3 oz of total beverage volume, had a similar mint character as the beer I brewed. I liked my version better, which surprised me because cold-steeping ingredients in alcohol (Creme de Menthe) usually results in a smoother character than boiling (my beer). Stepping up the Creme de Menthe to 1/2 tsp per 3 oz didn't really increase the "minty" flavor. Instead, it imparted a harshness that reminded me of overcarbonation due to brettanomyces (wild yeast) contamination. I found it vaguely offensive, but Rachel liked it. I now have two theories of mint beer that need to be explored:

1. Mint and hops don't like each other. Edmund Fitzgerald is a pretty hoppy porter, which may have caused the clash.

2. Mint flavor is desirable, but mint aroma is too aggressive for beer. My 5-minute boil may have driven off some of the mint's harshness, and a 15- or 20-minute boil may be even better.